![gongyebu-small[0].jpg](/../../upload/image/20221206/6380591950049425914307172.jpg)

Hand Lay-up Process

The reinforcement, in form of fiberglass strands, mat or woven roving, is first laid into a mold which has been coated with a release agent and a gel coat. Then a resin mix is applied by hand using a brush or spray gun. A roller is then used to ensure uniform impregnation, complete glass wet-out, and removal of any trapped air bubbles. This operation is repeated until the desired thickness of the structure is obtained. After curing at room temperature or under heating conditions, the finished parts are formed.

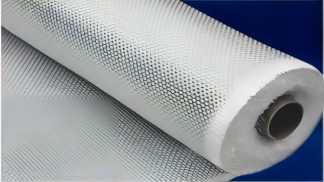

Woven Rovings

Woven Rovings are compatible with UP, VE, EP and PF resins.

Woven Rovings are available with a width range of 50mm 〜3,000mm and a weight range of 260g/m2 ,600 g/m2. Other specifications are also available on customer request.

Product Features

Woven Fabric Features and Benefits:

• Parallel, flat strand alignment with uniform tension

• Good drapability and conformability to radii

• Added stitched chopped strand mat is optional

• Fast wet-out and complete wet-through

• Easy roll-out and excellent air release

• High mechanical properties of the laminate

• Plain weave is standard, fits most applications

• Approved by Lloyd’s Register

End-Use Markets

STANDARD PRODUCTS

规格型号 Code | 玻璃类型 Glass type | 质量 Weight (g/m2) | 断裂强度≥N/50mm | 组织 Weave | 含水率% Moisture Content | 可燃物% L.O.I Content | |

Breaking strength | |||||||

经向Warp | 纬向Weft | ||||||

EWR200 | E/ECR | 200 | 1300 | 1100 | Plain | ≤0.2 | 0.4-0.8 |

EWR270 | E/ECR | 270 | 1900 | 1700 | Plain | ≤0.2 | 0.4-0.8 |

EWR300 | E/ECR | 300 | 2000 | 1800 | Plain | ≤0.2 | 0.4-0.8 |

EWR360 | E/ECR | 360 | 2200 | 2000 | Plain | ≤0.2 | 0.4-0.8 |

EWR400 | E/ECR | 400 | 2500 | 2200 | Plain | ≤0.2 | 0.4-0.8 |

EWR500 | E/ECR | 500 | 3000 | 2750 | Plain | ≤0.2 | 0.4-0.8 |

EWR530 | E/ECR | 530 | 3300 | 3000 | Plain | ≤0.2 | 0.4-0.8 |

EWR560 | E/ECR | 560 | 3500 | 3200 | Plain | ≤0.2 | 0.4-0.8 |

EWR580 | E/ECR | 580 | 3600 | 3300 | Plain | ≤0.2 | 0.4-0.8 |

EWR600 | E/ECR | 600 | 4000 | 3850 | Plain | ≤0.2 | 0.4-0.8 |

EWR720 | E/ECR | 720 | 4300 | 4150 | Plain | ≤0.2 | 0.4-0.8 |

EWR800 | E/ECR | 800 | 4600 | 4400 | Plain | ≤0.2 | 0.4-0.8 |

EWR1000 | E/ECR | 1000 | 5300 | 5100 | Plain | ≤0.2 | 0.4-0.8 |

EWR1200 | E/ECR | 1200 | 5900 | 5700 | Plain | ≤0.2 | 0.4-0.8 |

* Must specify fabric width Other constructions upon request

PRODUCT DATA

Type of Glass | E-glass glass formulation | |

Resin Compatibility | Polyester, Vinyl Ester & Epoxy | |

Coupling Agent | Silane | |

Linear Density (Tex or Yield) | Nominal ± 10% | |

Moisture (%) | ≤ 0.15% | |

Standard Construction | Balanced, 5 x 4 plain weave (Other constructions available upon request) | |

Packaging | Plastic bag wrapped, cylindrical rolls on side, 9 rolls per pallet | |

Roll Dimensions | Cylindrical 30cm ( 12.0” ) DIA x roll widths 15cm (6”) to 320cm (125”) | |

Roll Weights | 15 kg (32 lb) to 183 kg (403 lb) | |

Pallet Configuration |

Stretch Wrapped and Top Protected. Number of rolls and layers vary with roll width | |

Storage Recommendations | S (1) Do Not Double Stack | |

Remarks:

Roll width: Standard width in 1000mm,1270mm, and other sizes depends on customer’s real needs, available in 200mm to 3200mm.

Packing: Fiberglass woven roving is usually rolled in a paper tube with inner diameter 76mm. The roll is warped with plastic film, then put into carton. Lay the rolls horizontally, and can be loaded on pallets and bulk in container.

Storage: The product should be stored in a cool, water-proof area. It is recommended that the room temperature and humidity be always maintained at 15℃ to 35℃ and 35% to 65% respectively. Please keep the product in its original packaging before being used, avoiding moisture absorption.